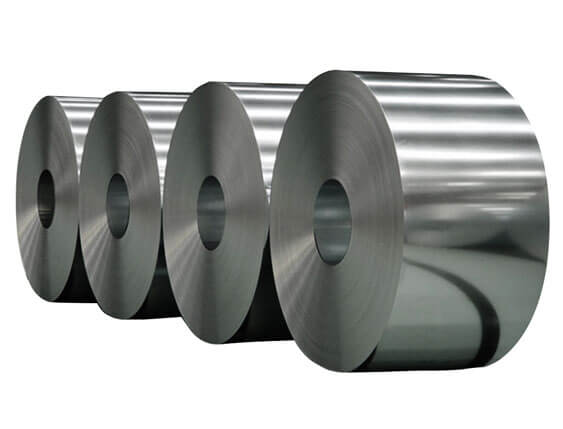

Duplex steel is a popular material in manufacturing due to its excellent strength, durability, and corrosion resistance. Two of the most common grades of duplex steel are S31803 and S32205. These alloys are widely used in various applications, including chemical and petrochemical processing, oil and gas exploration, marine engineering, and construction. Duplex Steel S31803 Coils is a two-phase microstructure consisting of austenitic and ferritic phases. Due to its unique composition, it offers superior resistance to both corrosion and chloride stress corrosion cracking than austenitic and ferritic stainless steels. S31803 duplex steel coils are available in different types: hot rolled, cold rolled, annealed, and pickled. These coils are widely used in various applications, such as heat exchangers, storage tanks, pressure vessels, and piping systems. S31803 coils are easy to fabricate, weld, and cut to size, making them ideal for various manufacturing processes.

Duplex steel S32205 is a nitrogen-enhanced duplex stainless steel that offers excellent resistance to pitting, crevice corrosion, and erosion corrosion. Compared to S31803, S32205 has better toughness and flexibility, making it suitable for high-stress applications. S32205 coils are commonly used in the chemical processing industry, where they are used in heat exchangers, pressure vessels, and storage tanks. They are also used in the oil and gas exploration industry, where they can withstand harsh environments and high temperatures. Duplex Steel S32205 Coils are also used in the marine engineering sector, where they can resist seawater corrosion and abrasion.