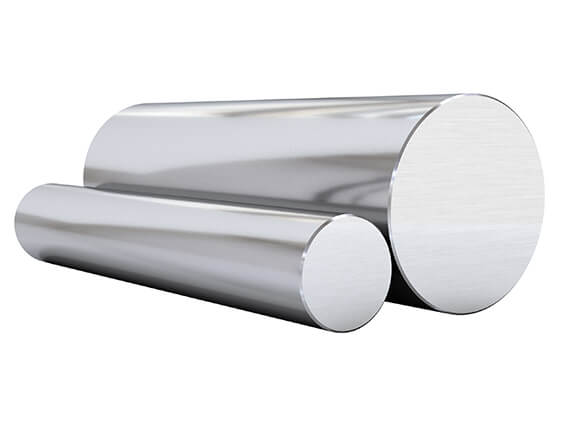

Hastelloy C22 is one of the most popular and versatile alloys in material science. Engineers and designers love Hastelloy C22 due to its exceptional corrosion resistance, making it an excellent choice for various applications. One of the best ways to use this alloy is by incorporating Hastelloy C22 round bars. Hastelloy C22 round bars come in different types, each with a unique use. The most common Hastelloy C22 Round Bars are hot-rolled, cold-rolled, drawn, and forged round bars. Hot-rolled bars are rough and have a scaly finish. Cold-rolled bars, on the other hand, are much smoother and have a bright finish. Drawn round bars are the most precise, as they undergo a tight tolerance process. Forged round bars undergo pressurizing and shaping into various shapes. Each Hastelloy C22 round bar type serves a particular purpose, depending on the application requirements.

Hastelloy C22 Round Bars are a cost-effective alternative to other corrosion-resistant alloys. They have many applications, including chemical, pharmaceutical, food, and petrochemicals. They are also used to construct heat exchangers, reactors, and heat-treating equipment. Hastelloy C22 round bars are incredibly versatile, making them an essential choice for any material science application that requires durability, strength, and chemical resistance.